4 Types of Geothermal Air Conditioning Systems for Your Home

A geothermal system can help you save a significant amount of money on home heating and cooling costs by lowering your energy use. These systems come in a few different types that offer their own advantages and disadvantages. The type of system that’s right for your home will depend on factors such as soil conditions and property size. Keep the following geothermal facts in mind when looking at systems for your home. Geothermal HVAC is becoming more popular among homeowners in Northwest Arkansas. It’s a cleaner and more efficient form of energy. It allows for more environmentally friendly and cost-effective heating and cooling. Understanding the options for geothermal HVAC makes it easier to determine which system will work best in your home.

As with any heat pump, geothermal and water-source heat pumps are able to heat, cool, and, if so equipped, supply the house with hot water. Some models of geothermal systems are available with two-speed compressors and variable fans for more comfort and energy savings. Relative to air-source heat pumps, they are quieter, last longer, need little maintenance, and do not depend on the temperature of the outside air.

A dual-source heat pump combines an air-source heat pump with a geothermal heat pump. These appliances combine the best of both systems. Dual-source heat pumps have higher efficiency ratings than air-source units, but are not as efficient as geothermal units. The main advantage of dual-source systems is that they cost much less to install than a single geothermal unit, and work almost as well.

Even though the installation price of a geothermal system can be several times that of an air-source system of the same heating and cooling capacity, the additional costs are returned to you in energy savings in 5 to 10 years. System life is estimated at up to 24 years for the inside components and 50+ years for the ground loop. There are approximately 50,000 geothermal heat pumps installed in the United States each year. For more information, visit the International Ground Source Heat Pump Association.

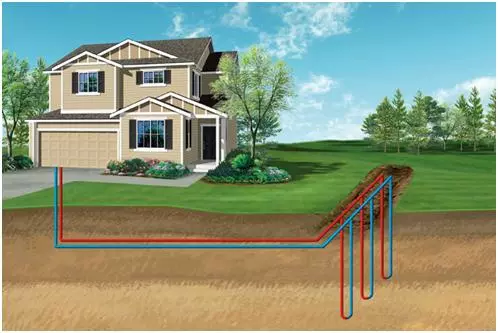

Vertical Closed-Loop Systems

These geothermal systems are commonly installed on residential properties in Northwest Arkansas, since they don’t require a lot of land and only have minimal effects on landscaping. Geothermal facts show that these systems typically involve having holes drilled roughly 20 feet apart and up to 400 feet deep. The pipes installed in these holes join together at the bottom and top, then connect to the home’s heat pump with a pipe.

It’s common for larger buildings to use vertical loop systems, including commercial facilities and schools. This system also uses closed loops. You can install it in areas with shallow soil or to minimize the disturbance to existing landscaping.

During the installation process, a service technician will drill holes measuring about 4 inches in diameter, 20 feet apart and 100-400 feet deep. They will then place pipes that connect at the bottom with a U-bend and at the top with a horizontal piece of piping to create the closed loop. After digging the holes and installing the pipes, they will connect the loop to your building’s HVAC system.

Most closed-loop geothermal heat pumps circulate an antifreeze solution through a closed loop — usually made of plastic tubing — that is buried in the ground or submerged in water. A heat exchanger transfers heat between the refrigerant in the heat pump and the antifreeze solution in the closed loop. The loop can be in a horizontal, vertical, or pond/lake configuration.

One variant of this approach, called direct exchange, does not use a heat exchanger and instead pumps the refrigerant through copper tubing that is buried in the ground in a horizontal or vertical configuration. Direct exchange systems require a larger compressor and work best in moist soils (sometimes requiring additional irrigation to keep the soil moist), but you should avoid installing in soils corrosive to the copper tubing. Because these systems circulate refrigerant through the ground, local environmental regulations may prohibit their use in some locations.

Large commercial buildings and schools often use vertical systems because the land area required for horizontal loops would be prohibitive. Vertical loops are also used where the soil is too shallow for trenching, and they minimize the disturbance to existing landscaping. For a vertical system, holes (approximately four inches in diameter) are drilled about 20 feet apart and 100 to 400 feet deep. Into these holes go two pipes that are connected at the bottom with a U-bend to form a loop. The vertical loops are connected with horizontal pipe (i.e., manifold), placed in trenches, and connected to the heat pump in the building.

Horizontal Closed-Loop Systems

These systems require a larger amount of land and can interfere more with landscaping. Based on geothermal facts, these systems are not suitable for properties with rough, rocky soil. Therefore, they’re not typically installed in Northwest Arkansas. Installers dig trenches that are at least four feet deep, then bury two pipes in the ground lengthwise.

Horizontal loop systems require more space. Therefore, you’ll need a larger lot to accommodate this option. A horizontal loop is always closed, allowing liquid to move continuously through the loop. This style of system requires at least 400-600 feet of looping space beneath the ground for every ton of cooling and heating capacity the household requires. Your HVAC service technician can perform a load value calculation to determine your heating and cooling needs before making a plan.

In a horizontal loop system, the service technician will dig trenches measuring 3 to 6 feet in depth. They will bury the loops in these trenches. Some service technicians offer a “Slinky” method of installing the pipes, which reduces the sizes of the trenches and lowers the installation costs. With this method, smaller properties might be able to accommodate horizontal loop systems.

This type of installation is generally most cost-effective for residential installations, particularly for new construction where sufficient land is available. It requires trenches at least four feet deep. The most common layouts either use two pipes, one buried at six feet, and the other at four feet, or two pipes placed side-by-side at five feet in the ground in a two-foot wide trench. The Slinky™ method of looping pipe allows more pipe in a shorter trench, which cuts down on installation costs and makes horizontal installation possible in areas it would not be with conventional horizontal applications.

Pond Loop Systems

Geothermal facts indicate that these systems do not involve much digging or drilling. Instead, a coiled pipe is placed about eight feet below the surface of a nearby pond, while a supply line pipe is installed in the ground from the pond to the home’s heat pump. Pond loop systems can only be used if the pond has enough depth and volume, as well as good water quality.

Pond/lake loop systems are also low-cost options for property owners with access to a pond or a lake. The system is closed, and installation requires some digging to attach the underground components to the indoor elements of the system. These aren’t as common, since many people don’t have lakes or ponds on their properties. But if you do, it’s the perfect option.

If the site has an adequate water body, this may be the lowest cost option. A supply line pipe is run underground from the building to the water and coiled into circles at least eight feet under the surface to prevent freezing. The coils should only be placed in a water source that meets minimum volume, depth, and quality criteria.

Open-Loop Systems

In closed-loop systems, a heat exchange fluid circulates through the pipes. With open-loop systems, surface water or well water runs through pipes and goes directly back into the ground. Open-loop systems require a clean supply of water, and geothermal facts show that they are not allowed in certain areas.

This type of system uses well or surface body water as the heat exchange fluid that circulates directly through the GHP system. Once it has circulated through the system, the water returns to the ground through the well, a recharge well, or surface discharge. This option is obviously practical only where there is an adequate supply of relatively clean water, and all local codes and regulations regarding groundwater discharge are met.

Air Conditioning Resources

Air Conditioning

Does Closing Vents Redirect Air Throughout Your Home?

Air Conditioning

R-22 Refrigerant Phase-Out: What to do if you Have an R-22 HVAC System