Want to save with Paschal? Don’t miss our current offers and specials

Want to save with Paschal? Don’t miss our current offers and specials

Return to Paschal Resource & Education Hub

Welcome to our comprehensive guide on addressing one of the most common yet perplexing issues faced by homeowners: a weak flushing toilet. This problem, seemingly minor, can significantly disrupt daily life, indicating underlying issues within your plumbing system that require attention. Our goal is to equip you with the knowledge and steps necessary to tackle this issue head-on, ensuring your toilet functions efficiently and effectively. Throughout this article, we’ll explore the intricacies of toilet mechanics, identify common culprits behind weak flushing, and provide you with detailed, actionable solutions. From DIY fixes to when to call in the professionals, this guide will be your go-to resource for restoring your toilet’s performance.

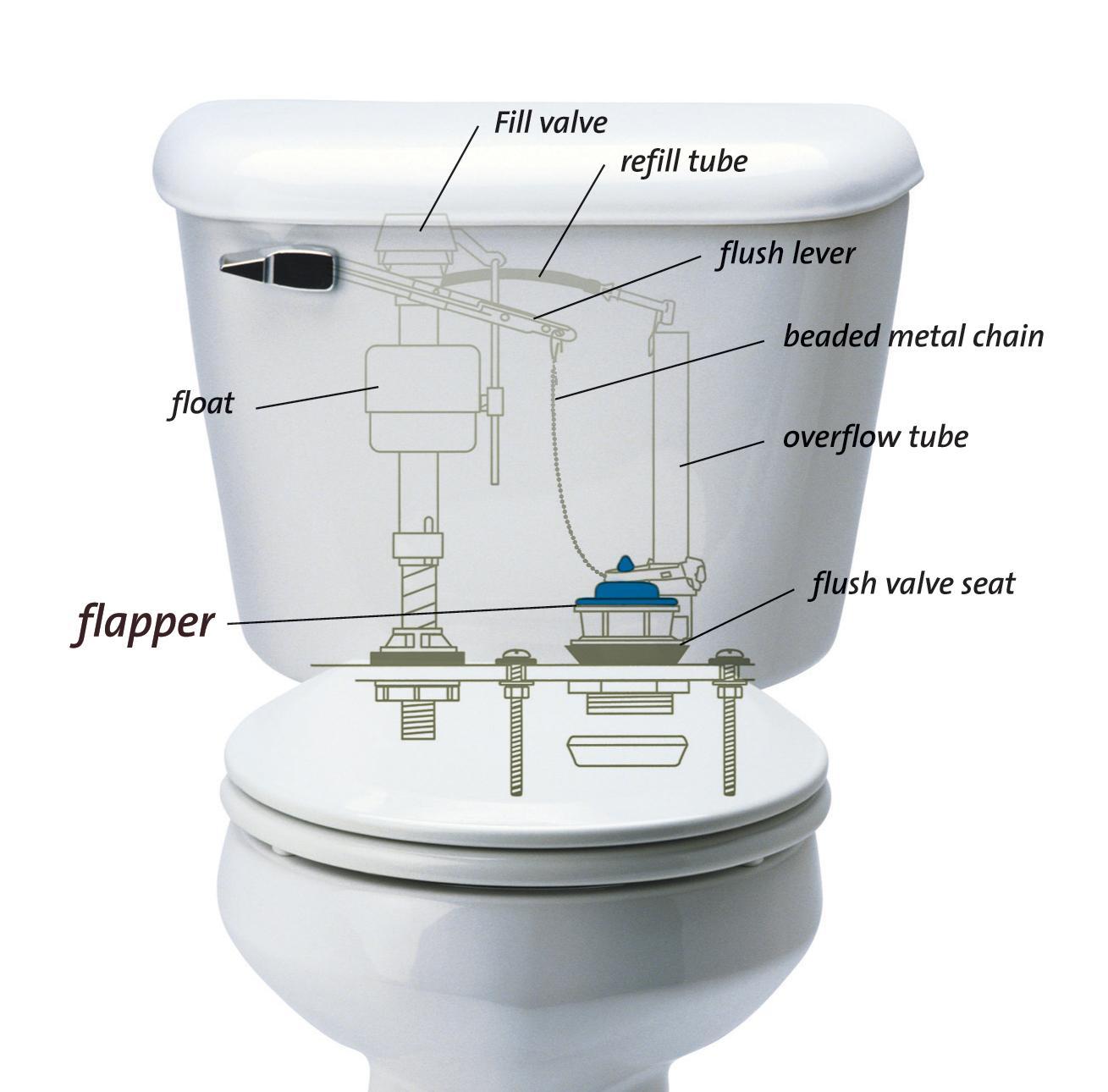

The mechanics behind a toilet’s flush are both fascinating and fundamental to addressing any issues that arise. A toilet operates on a simple yet ingenious mechanism involving water flow, gravity, and a siphoning effect that ensures waste is effectively removed from the bowl. Central to this process are the toilet’s tank, where water is stored and released for flushing, and the bowl, where the actual flush takes place. Key components such as the flapper, fill valve, and rim jets play critical roles in this system. An understanding of these components and how they interact provides the foundation for diagnosing and fixing flushing problems.

Weak flushing can be attributed to several factors, each affecting the toilet’s efficiency in different ways. Here, we delve into each cause, from clogged rim jets that reduce water flow into the bowl to misadjusted water levels that fail to provide the necessary force for a powerful flush. Solutions range from cleaning and maintenance to part replacements, all aimed at restoring optimal function.

Rim jets play a crucial role in the flushing mechanism by directing water into the bowl. Over time, these can become clogged with mineral deposits from hard water, reducing the flow of water into the bowl during a flush. This decreased flow results in a weaker flush, as there isn’t enough water force to effectively clear the bowl.

The amount of water stored in the toilet tank directly influences the flushing power. If the water level is set too low, there simply isn’t enough volume or pressure to create an effective flush. This issue can arise from incorrect adjustments of the tank’s float or from wear and maladjustment over time.

The flapper valve is responsible for releasing water from the tank into the bowl when the toilet is flushed and then sealing the tank for refilling. If the flapper doesn’t open fully, closes too quickly, or has a poor seal due to wear, it can significantly impact the flush by not allowing enough water to flow from the tank to the bowl in a timely manner.

Most toilets feature a siphon jet, which is designed to boost the flushing power by directing a strong flow of water into the bowl. Similar to rim jets, the siphon jet can become clogged with mineral deposits, which diminishes its effectiveness and, in turn, the overall flush power.

The plumbing vent pipe, which allows air into the plumbing system to help regulate pressure, can become blocked by leaves, debris, or even nests. A blocked vent pipe disrupts this air balance, leading to poor flushing performance as the necessary air flow to facilitate a strong flush is compromised.

The flush valve system, which includes the flapper, the lift chain, and the valve seat, can become inefficient due to wear or improper adjustment. Problems in this system can lead to partial flushes or leaks that reduce the available water for a full flush.

Certain toilet designs, particularly older models or first-generation low-flow toilets, inherently have weaker flushing capabilities. Additionally, improper installation can affect the toilet’s ability to flush properly, such as if there’s an issue with the alignment or sealing of the toilet to the floor or plumbing.

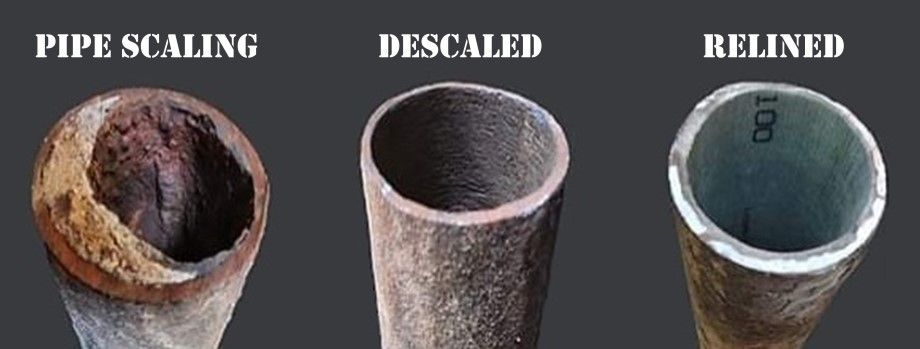

In areas with hard water, scale buildup inside the pipes can restrict water flow to the toilet. This reduced water flow can affect the fill rate of the tank as well as the pressure and volume of water available for each flush, leading to weaker flushing action.

The water supply valve to the toilet can become partially closed or blocked, reducing the flow of water into the tank. This issue can be gradual, resulting from mineral buildup, or sudden, if the valve is accidentally turned or damaged.